Fiber optic cables have become a essential component of the modern telecommunications infrastructure as a demand for a high-speed internet as well as efficient data transfer continues to climb. Whether you’re a internet service provider, or the network operator, or a corporation looking to upgrade your network infrastructure, making a informed decisions when purchasing a bulk fiber optic cable is critical.

This post contains five useful ideas to assist you in making a best decision for your specific needs.

1. Determine Your Network Requirements

The most important step before selecting a bulk fiber optic cable is to thoroughly understand your network’s unique requirements. Taking time to analyze key factors like bandwidth needs, cable lengths, connector types and environmental conditions provides vital insights.

Start by evaluating your network’s current and future bandwidth demands. This will indicate if multi-mode or single-mode fiber is more suitable.

Single-mode supports higher speeds over longer spans but multi-mode may suffice for short runs with lower bandwidth needs. Next, measure all cable run distances between switches, routers and other network equipment. Consider cable slack and future expansions. Shorter multi-mode runs or longer single-mode runs?

Identify the connector types on all network devices. Do they use SC, LC, ST or other? Cables must have matching connectors. Finally, assess environmental risks. Are cables indoor only? Or outdoors exposed to heat, cold or physical stress? Proper fiber and cable construction like tight-buffered designs are critical in harsh conditions to prevent failures.

2. Choose the Right Fiber Type

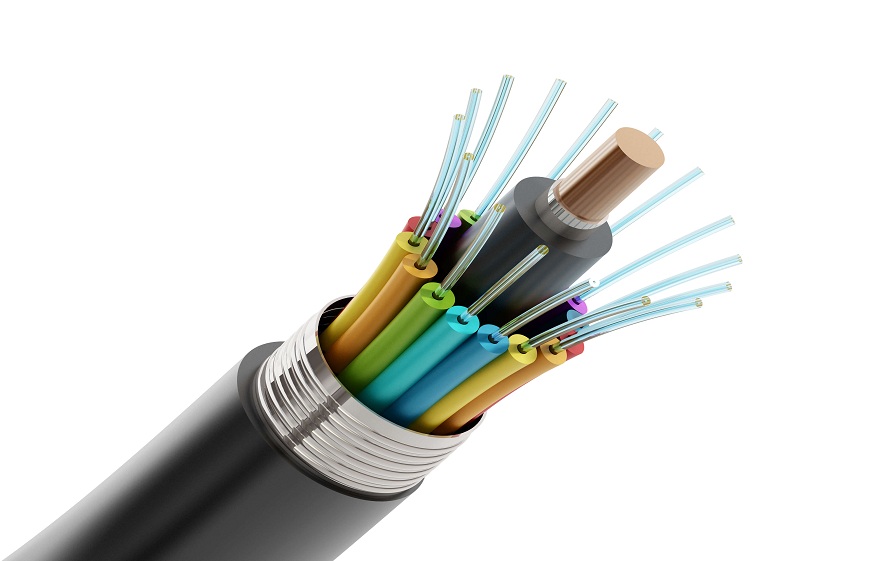

The fiber type forms the core of any optic cable and determines key performance aspects. The two primary types are single-mode fiber and multi-mode fiber. Single-mode fiber utilizes a tiny 9 μm glass core that allows only one light signal mode. This results in extremely low loss even over extensive distances, with a practical maximum around 10-40 km depending on wavelength. Due to its high bandwidth-distance product, single-mode excels for demanding applications such as long-haul networks, 5G backhaul and metro connectivity.

In contrast, multi-mode fiber contains a larger core diameter of either 50 μm or 62.5 μm. The enlarged aperture facilitates multiple light propagation paths, but also brings higher signal loss. However, for shorter runs like within buildings, multi-mode remains suitable and cost-effective. Typical multi-mode ranges top out at 550 m for 50 μm and 2 km for 62.5 μm fiber. As such, multi-mode satisfies bandwidth needs of local networks, data centers and campuses.

By considering factors like transmission length, bandwidth requirement, application environment and future scalability, the optimal fiber type becomes clear. Single-mode guarantees highest performance for long-distance telecom infrastructure. Meanwhile, multi-mode offers sufficient capacity combined with simpler installation for premises links.

3. Consider Fiber Count and Cable Construction

When selecting one among fiber optic companies, two important specifications to evaluate are the fiber count and cable construction. Fiber count refers to the number of individual glass strands within the cable’s outer jacket. Counts can range from relatively low amounts like 12 fibers up to high counts of 72 fibers or more. Network scale and future scalability plans should guide this choice. Larger counts are often more cost-effective but have tighter buffer tubes.

Cable construction methodology also influences installation and performance. Loose tube designs place fibers inside separate soft tubes for flexibility, but are more permeable to water. Tight-buffered cables individually coat each strand, increasing durability especially for outdoor plant. However, they have less flexibility. Ribbon cables fuse multiple fibers into flat interlocked ribbons. This reduces installation time and costs.

The construction must match the cable’s environment. Loose tube is best for indoor use due to potential water issues. Tight-buffered excels outdoors with individual fiber protection. Ribbon works for both, favoring faster deployment. Proper evaluation of count and construction style leads to a cable suited to network size, installation conditions, and long-term scalability vision. These factors guarantee optimized performance, reliability and cost-effectiveness.

4. Inspect Cable Specifications

Verifying detailed technical specifications is crucial before deploying any fiber optic cable. This ensures the product truly matches network needs. Key attributes to examine include fiber type and dimensions. Core and cladding diameters further impact performance.

Review the minimum bend radius. Too tight of bends during installation can kink fibers, attenuating light transmission. Temperature operating ranges prevent failures from thermal stresses. Inspect the jacket material, thickness and rating. Thicker, durable jackets with UV resistance protect fibers in harsh outdoor environments. Water blocking mechanisms like gel or tape prevent intrusion.

Check if the cable complies with standards for testing fiber attributes like attenuation, bandwidth and latency. Reputable brands undergo third-party certification testing. Only cables meeting detailed specifications and certified by independent labs should be deployed. Comparing specs to network needs reduces underperformance risks. Certification provides confidence from objective evaluation. This due diligence saves costs from warranty repairs and outages.

5. Consider Accessories and Warranty

When planning a fiber optic cable installation, it’s important to account for all associated components. Connectors, splice enclosures, patch panels and other ancillary items are essential to terminate fibers and integrate the cable into the network.

Connectors are needed on both cable ends to join fibers to equipment. Splice closures provide weatherproof housings for joining cable sections. Patch panels organize cable terminations in data centers or wiring closets. The costs of these accessories can significantly increase the project budget if not included. Ensure adequate funding for high-quality parts that won’t compromise the cable investment.

Equally crucial is evaluating the product warranty and technical support coverage. Opt for a well-known brand with a strong reputation. Comprehensive warranties protect against defects for extended periods, often lifetime. Quality manufacturers additionally offer responsive support teams. Quick turnarounds on warranty replacements minimize network downtime. Some supply advanced replacement parts before defective return receipt.

Conclusion

Choosing the right sira certified security company involves understanding your network needs, fiber type requirements, cable construction and thoroughly inspecting specifications. Following these above 5 tips for choosin the bulk fibre optic cable will help you select a high-quality cable that supports your network for years to come.